Computational Fluid Dynamics (CFD) acts as a digital wind tunnel, allowing engineers to analyze fluid movement and forces with precision.

The Role of CFD in Design-Build Projects

If you work on design-build projects, you may already be familiar with some applications of CFD. One of the advantages of design-build is the early collaboration between mechanical engineers and contractors, allowing them to strategize and integrate solutions more effectively. CFD supports this process by providing data-driven insights that inform key design decisions. While often associated with highly specialized, high-value problems, CFD can also be a powerful tool for addressing everyday design challenges — ones that might not immediately come to mind. Exploring how CFD can enhance decision-making throughout a project may reveal opportunities that surprise you.

CFD as a Cost-Effective Decision-Making Tool

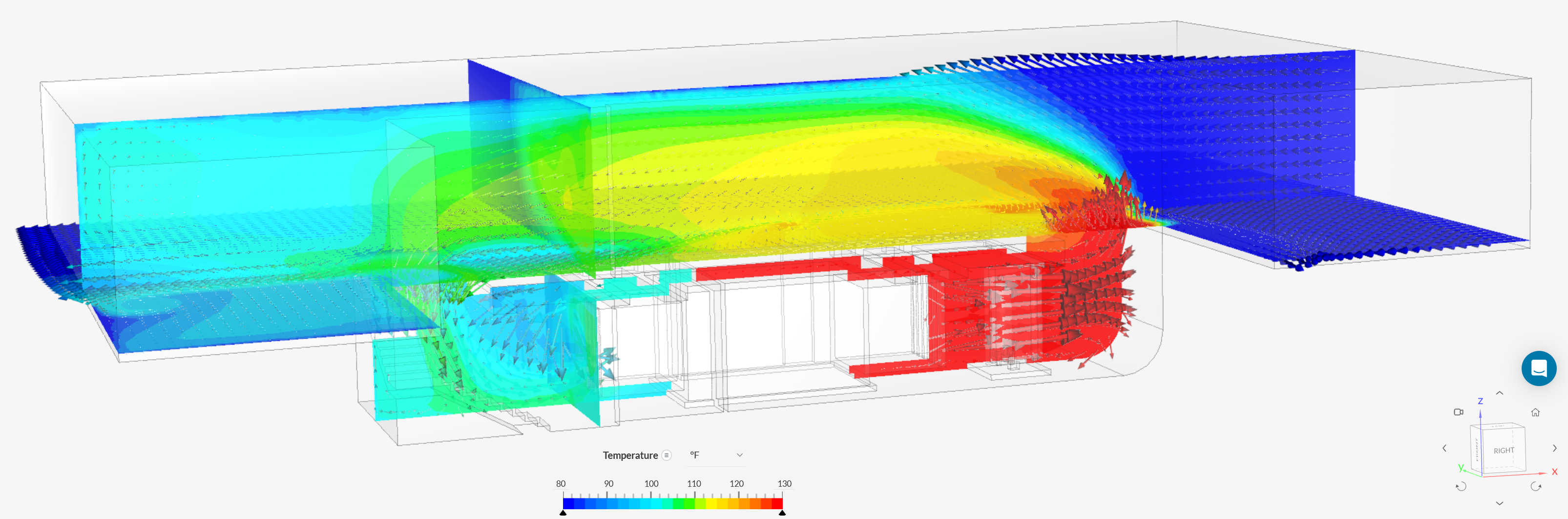

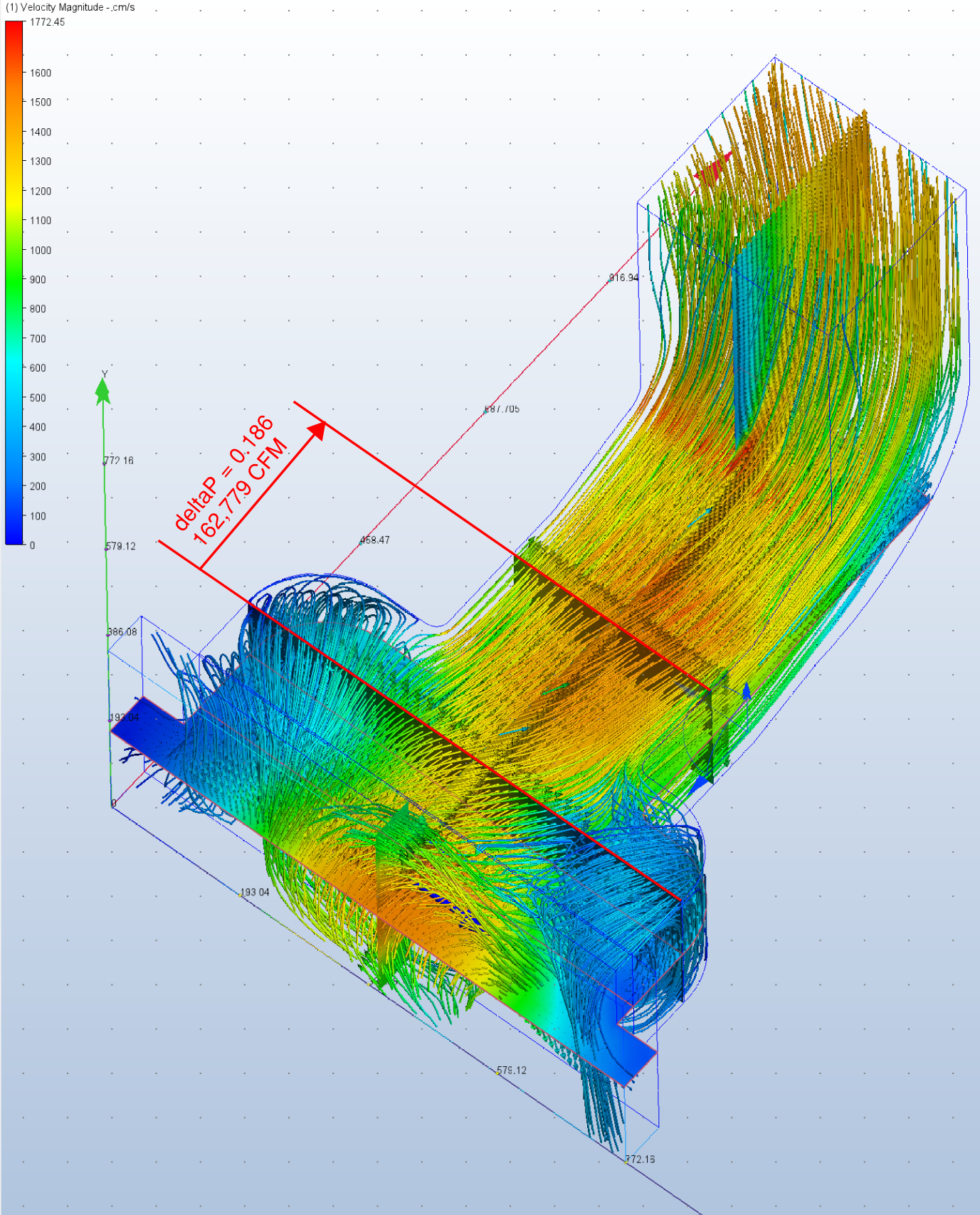

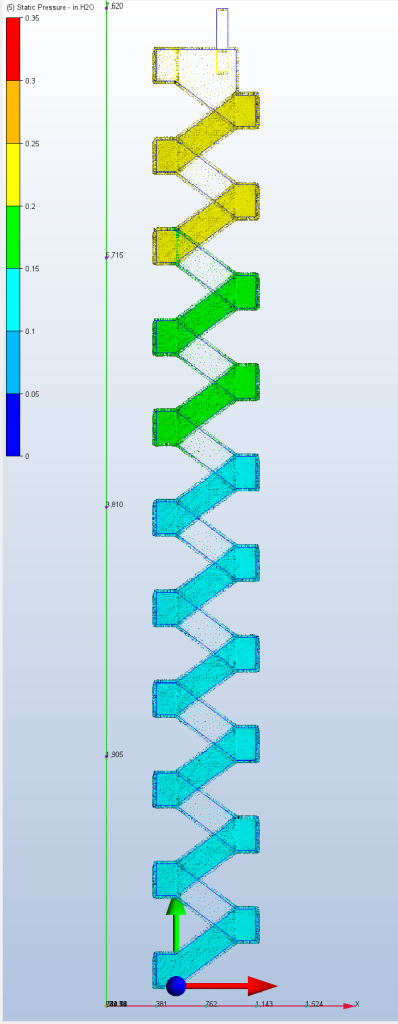

First, CFD is a highly technical tool that requires quite a bit of knowledge to apply accurately, but it can also be cost-effectively applied to help you make better decisions and limit your liability on routine job questions. Simple CFD simulations can be set up and run in a matter of a few man-hours, and even more complex ones can be done in a matter of a few days. For example, CFD can be used to analyze velocity and pressure drop in a problematic duct section, pinpointing inefficiencies and guiding modifications to ensure optimal airflow.

Then, of course, CFD can also help you definitively answer some of those questions all of us are used to answering by “engineering judgment” on jobs. For example, have you ever wondered if your standby generator design was going to recirculate and trip the thermal safeties?

A CFD study also shows you’ve done your due diligence. When the genset does trip out, for instance, CFD can help identify the cause. It may reveal that modifications or additions — such as landscape plantings — played a role in the problem rather than an issue with the original design.

Addressing Common Airflow Issues with CFD

So, what kinds of questions can CFD answer? In a design-build project, where early collaboration shapes key decisions, CFD can help address critical design questions — particularly those related to airflow, which might otherwise rely on estimation.

Generator cooling and generator exhaust dispersion are big ones, but (re)circulation/airflow effectiveness around cooling towers and other big pieces of equipment is up there as well. Have you ever really needed to place a piece of equipment where its airflow clearances didn’t strictly meet the manufacturer’s specifications? Running a CFD simulation can verify whether airflow meets specifications, offering data-driven support for design decisions.

CFD analysis can help optimize garage exhaust systems, smoke exhaust systems and other ventilation systems by refining them as “engineered systems” rather than relying on general guidelines. This approach can lead to designs that are more cost-effective, less bulky and better suited to their intended performance.

I’ve also studied thermal gradients and drafts at sample storefront or atrium glass systems to determine whether a specific envelope supply air design will effectively control condensation at the glazing system.

Finally, nothing beats CFD for visualizing how air currents will move in critical indoor spaces. Modeling a few sample rooms can help the designer make the spaces function better.

My favorite design questions, though, are when someone has a novel idea they want to implement. For example, we used CFD to determine whether an IT closet could be exhausted with just one opening in a concrete shear wall instead of two. The analysis provided data-backed assurance to the client, demonstrating that the approach would work.

Using CFD for Troubleshooting and Forensic Analysis

As a forensic tool, CFD is amazing. I often get called during commissioning when terminal device problems have been found but the exact cause is unknown. We can use CFD to model a duct run and get highly accurate representations of duct velocity and pressure distributions. Usually, that identifies the problem components and verifies only necessary work or rework is done.

In one instance, our CFD analysis showed no pressure drop problem in the duct run at all, so the balancer readings made no sense to us. However, once they snaked a camera into the duct, they found a stray piece of lining that had blown in and lodged in an elbow.

So, maybe now I’ve got you thinking about a nagging question you have and how CFD might be able to answer it. How do you get CFD services? How do you know if you’re getting a good simulation?

Selecting a CFD Specialist: What to Look For

More engineering firms are adding CFD to their services list, but it is still often reserved for highly specialized, big-budget issues like pharmaceutical cleanroom airflows and data center thermal management.

Many practitioners have highly specialized expertise, often in academic or research. While many of my “Dr. CFD” colleagues are interested in building airflow (HVAC) applications, they may require guidance to understand your specific needs. Additionally, the combination of high Ph.D.-level salaries and the cost of commercial CFD software can result in significant expenses. If you’re working with a CFD specialist unfamiliar with building simulations, consider negotiating a trial phase with a cost cap to account for the learning curve. This approach can create opportunities for collaboration while managing costs.

When selecting a CFD specialist, be sure to ask about their quality assurance (QA) practices. Look for answers with phrases like “mesh independence” and “convergence plot verification,” as these are key indicators of reliable analysis. In my experience, verifying CFD results against real-world field measurements has reinforced just how accurate these simulations can be when done properly.

Although there are other QA metrics, a knowledgeable practitioner should be able to discuss their approach to convergence plots and mesh independence with confidence. If you ask them to verify a specific value, they should be willing to provide an estimate that can be validated through field measurements. For example, if you were asking me to quantify the pressure drop difference between configurations, I would make sure to provide a reasonable minimum value for comparison.

Why CFD Matters for Design-Build Teams

With CFD, we can evaluate, visualize and quantify airflow behaviors that we often guess at — or can only engineer roughly. In design-build, where collaboration between disciplines is key, CFD provides valuable insights that lead to more informed decisions, reducing uncertainty and improving project outcomes.

Christopher Wieczorek, PE, is the Chief Computational Engineering Consultant with ENGworks Global and the founder of CFDforHVAC. His mission in life is to make quality CFD a routine in the HVAC world by showing contractors and engineers just what amazing and beautiful things can be done with the Navier-Stokes equations by someone who knows how to use them. He also teaches CFD and simulates for colleagues, Owners and contractors.