Winner of DBIA’s Best in BIM/VDC Award, this project highlights the innovative use of technology to redefine airport design and operations.

Walking into the newly transformed Nashville International Airport (BNA), it’s hard to believe this modern, art-filled space was once a 35-year-old terminal. However, behind the seamless design lies the story of cutting-edge technology and innovation that made it all possible.

The groundbreaking use of Virtual Design and Construction (VDC) in this renovation redefined what’s possible in airport design. The Nashville International Airport Terminal Lobby and International Arrivals Facility is a remarkable 780,000-square-foot renovation project that elevated one of Music City’s most beloved landmarks into a modern facility that improves operational efficiency and enhances the passenger experience. Leveraging advanced VDC tools and methods, the project team integrated innovative technology to address complex challenges and achieve design-build excellence, for which the project was recognized with DBIA’s Best in BIM/VDC Award in 2024. The project also received a National Award of Merit and a National Award of Excellence in the Aviation category in last year’s DBIA Awards. The project is a continuation of BNA’s Vision program dedicated to grow and expand the Nashville International Airport as a world-class facility for the future of Nashville. The project was a direct follow up to a previously completed Hensel Phelps project, the Nashville International Airport Concourse D and Terminal Wings, winner of the 2021 DBIA’s National Award of Merit and a National Award of Excellence in the Aviation.

The DBIA Project/Team Awards celebrate the nation’s most innovative and collaborative design-build projects. Learn more about winning projects like Nashville International Airport, and stay tuned for the 2025 awards cycle opening soon.

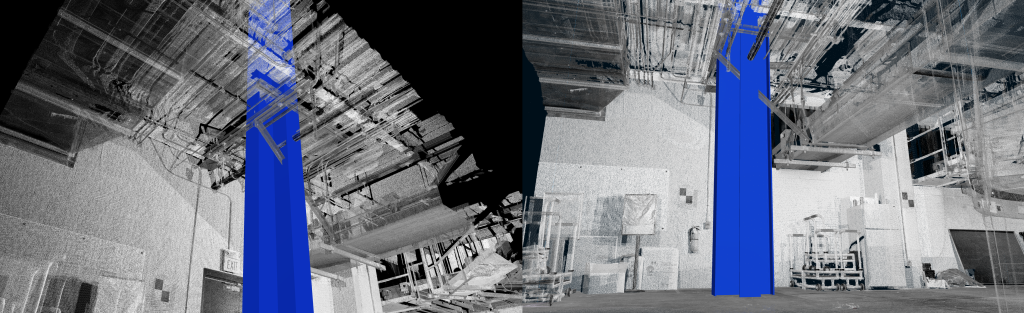

Precise Laser Scanning for Structural Optimization

The team conducted over 1,200 laser scans of the existing building early in the project to capture real world conditions while the design was still in its infancy. Creating a perfect virtual map of the building, the scans helped solve large challenges like replacing 88 support columns with just 32 — bringing to life the airport’s vision of creating a bright and open space. Given the increased size of the columns and their potential to impact multiple floors, the scan data allowed virtual reviews of their placement to ensure minimal disruption. These efforts preserved essential airport operations such as the baggage handling systems which remained fully functional throughout the project. This strategic use of technology not only met Metropolitan Nashville Airport Authority’s (MNAA) operational goals, but it also cemented their trust in the project team.

Augmented Reality for Design Intent and Maintenance

Augmented Reality (AR) was a transformative tool in this project that enabled virtual mockups of design elements to be reviewed in their exact locations. The team used AR to finalize finishes, including intricate terrazzo floor designs, with over 2,000 square feet of artistic green walls and BNA’s vendor concession spaces. Beyond aesthetics, AR facilitated practical reviews of MEP systems with MNAA’s facility and maintenance teams ensuring future access and functionality. AR also supported the fire marshal’s early inspections of life safety systems, expediting the project’s Temporary Certificate of Occupancy (TCO).

Robotic Layout for Enhanced Precision

The team utilized robotics to layout the complex security terminal configurations. This technology ensured consistent digital layouts accurately identifying equipment penetrations and clearances for security stations. By automating this traditionally time-consuming process, the team significantly improved efficiency and accuracy, allowing the team to meet strict project timelines without compromising quality.

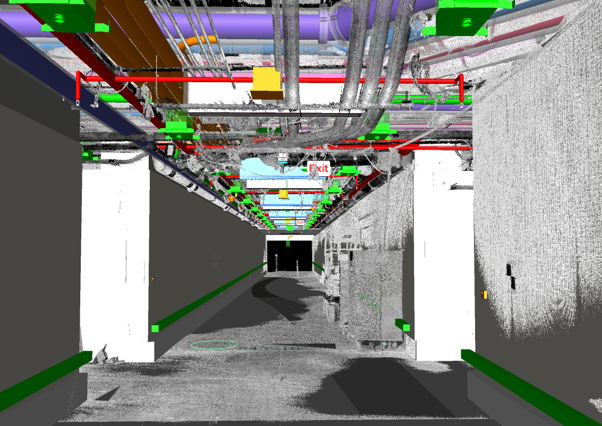

Laser Scanning for Tunnel Installation

One of the most intricate features of the project was the tunnel connecting the existing terminal to international arrivals. Spanning 200 feet with two sloping ramps, the tunnel’s artistic mural features an optical illusion that spells “Music City Nashville.” The laser scanning technology ensured strict alignment of panel systems, which avoided creating visual distortions in the mural. Additionally, periodic scans during installation addressed potential misalignments to maintain the mural’s integrity and deliver a lively passenger experience.

Real World Integration

Reality capture technology played a key role in accurately calculating sand fill for connecting slabs between new and existing construction. With 1mm precision, the scans documented real world conditions, enabling efficient material planning and ensuring structural stability. This proactive approach minimized waste and streamlined construction.

Technology Beyond BIM

The team also deployed digital tools like barcode readers for tracking steel deliveries and installations as well as interactive walkthroughs of passenger experiences with phasing walls and routing. These tools enhanced coordination and transparency, aligning the team with MNAA’s vision for a seamless traveler experience.

This project demonstrated that strategically applying VDC tools, coupled with a culture of innovation and collaboration, can redefine construction excellence. With MNAA’s support and the project team’s ingenuity, the Nashville International Airport Terminal Lobby and International Arrivals Facility set a new benchmark for technology integration in aviation projects.

As Virtual Design & Construction Manager at Hensel Phelps, Jason De Melfi is highly skilled at coordinating various design disciplines utilizing Building Information Modeling (BIM) technology. He works closely with design teams and trade partners to facilitate constructability reviews and to develop efficient solutions regarding the coordination of building systems among various disciplines. Additionally, De Melfi supports procurement needs for animations and renderings throughout the pursuit process. He is responsible for managing the Mid South’s VDC team and ensuring each project has the necessary training and resources to be successful.