At DPR Construction, models are deeply integrated into every step of the design and construction process. Project teams continuously visualize, simulate, attach data and track results, leading to greater predictability of cost, schedule and quality for the critical-path scopes DPR self-performs. This success stems from early collaboration with design partners, allowing VDC experts to align detailed modeling efforts with design intent.

On complex high-rise projects in Austin, Texas, DPR’s concrete VDC team uses structural modeling techniques to proactively resolve issues long before they might otherwise be encountered in the field. Through this process, DPR realizes tangible ROI from its modeling efforts. The concrete VDC process underscores the value of bringing together builders and designers early in the project lifecycle, offering lessons that can be applied to future design-build projects.

An Urban High-Rise

The Indeed Tower is a 39-story Class A office tower located in the heart of Austin’s Central Business District, offering more than 1.4 million sq. ft. of commercial space. The structure includes a 17-level garage with five sub-grade levels and 12 above-grade levels situated directly beneath the office floors. Both the office building and the garage feature a cast-in-place concrete structure with a full curtain wall exterior. DPR’s self-perform concrete craftsmen placed more than 79,000 cubic yards of concrete across 96 slab pours to complete the structure.

The strategies used on projects like Indeed Tower — early modeling, integrated teams and virtual coordination — mirror the core principles of Design-Build Done Right® and deliver even greater impact when applied in collaborative delivery environments.

Where Concrete Meets Steel

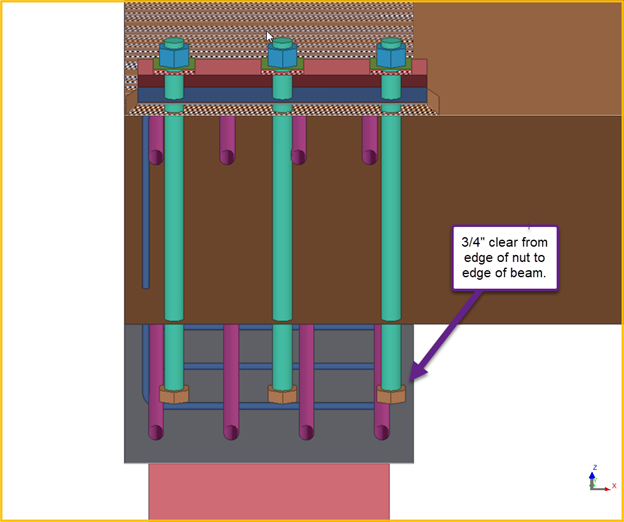

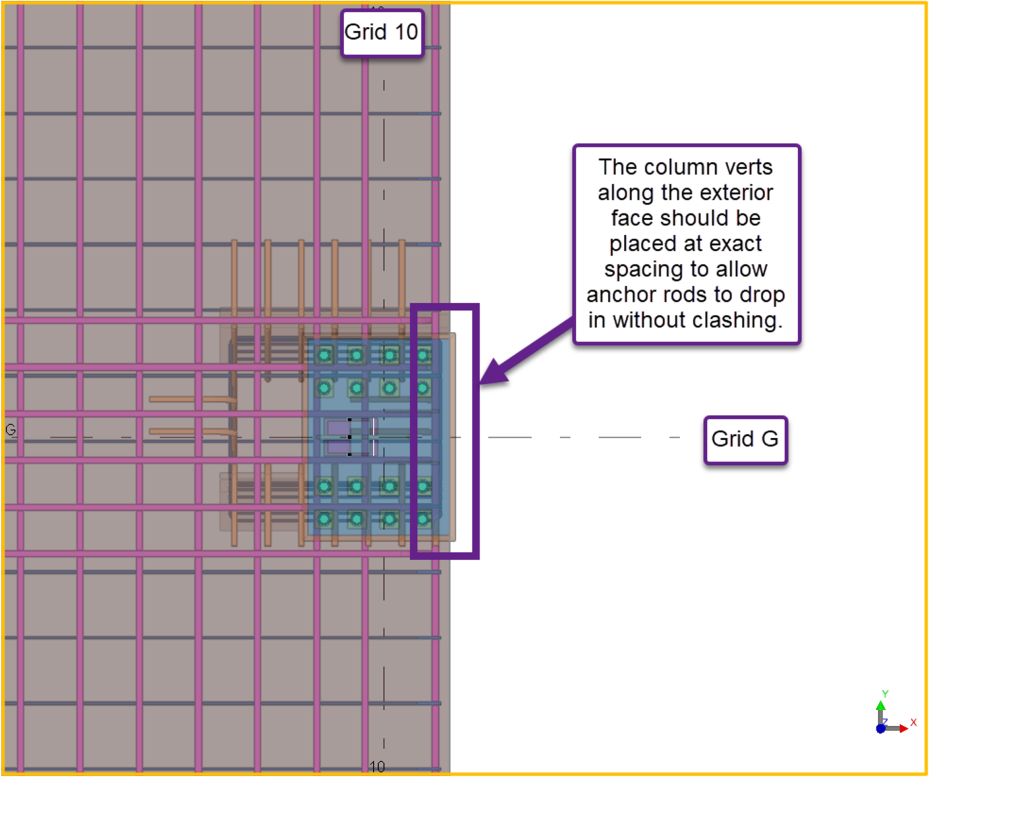

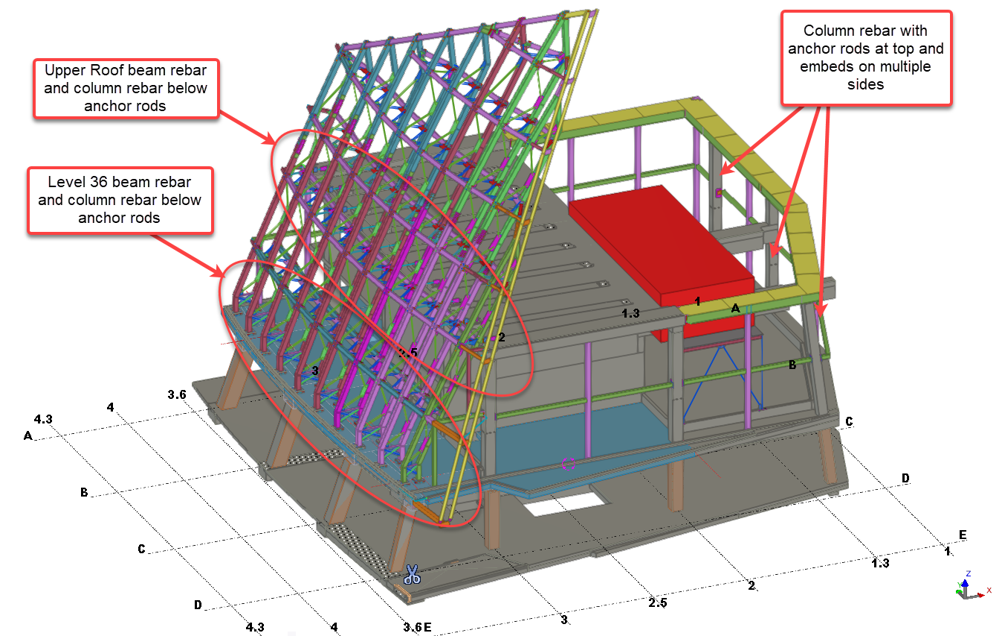

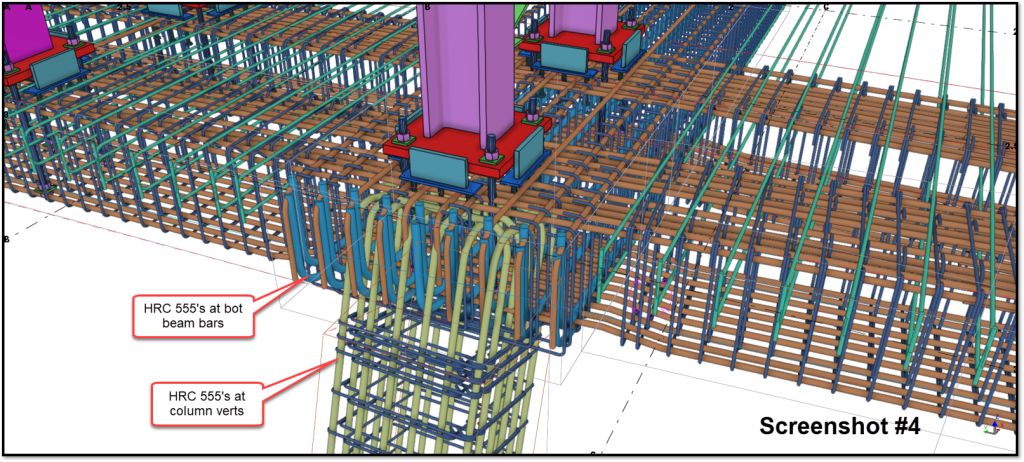

The final and highest concrete slab included large anchor rods to support a structural steel crown. While reviewing the sequence visualization for the overall project, DPR’s self-perform concrete team identified the crown connection as a high-risk condition and coordinated a virtual mock-up. By modeling every structural element, including reinforcement, the team uncovered multiple conflicts between the anchor rods and the slab.

To resolve these issues, the team widened several beams to accommodate the anchor rods and adjusted their layout to allow rebar to pass through. Because DPR was engaged early in the design, the team had the flexibility to propose and implement these changes well before they posed any risk to the construction schedule.

This early discovery allowed the team to adjust both the beams and anchor rod spacing during the design phase, avoiding conflicts before erecting the concrete formwork. The rebar fabricator received the updated column layout to meet the new spacing requirements.

Results

Without the sequence visualization revealing the need for additional structural modeling and coordination, the team likely wouldn’t have discovered the structural issues until just before pouring the final slab and preparing the anchor rods. Early collaboration with the engineer helped avoid an estimated $60,000 in rework and significantly reduced the risk of last-minute field modifications. Model-based planning also improved the safety, reliability, predictability and quality of the work.

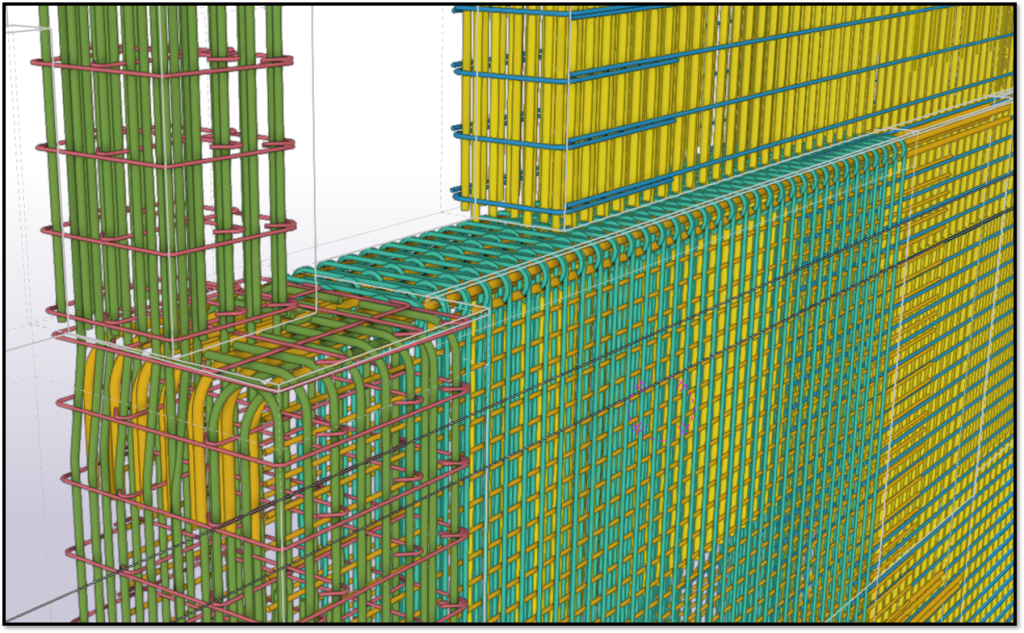

Scaling Structural Modeling

DPR has applied detailed structural modeling on numerous high-rise projects across Austin’s skyline. On one such project, the team modeled the rebar at the building’s crown after identifying potential issues in the details where the crown structure connected to the concrete. The rebar was then coordinated with both the steel and post-tensioning systems. This virtual approach helped eliminate what would have amounted to approximately $72,000 in rework costs for DPR’s concrete team. As with previous projects, early-stage alignment with the design team gave DPR’s concrete VDC experts the ability to resolve issues well before they could materialize in the field.

DPR’s modeling efforts also deliver value on residential projects. On one residential tower, the VDC team modeled rebar for the entire structure to validate the tonnage provided by the rebar fabricator against the structural engineer’s specifications. Using rebar weights generated from the model, the team identified $700,000 in savings for the client.

Collaboration between DPR’s self-perform concrete experts and the structural engineer through a virtual model led to tangible cost savings, schedule certainty and improved quality. These results were replicated across multiple projects in Austin, prompting DPR to scale this delivery process across all self-perform concrete projects. By implementing a design-build delivery method, projects can foster early engagement between builders and designers — unlocking similar benefits.

Read more about the Indeed Office Tower and other DPR project case studies on DPR’s website, and explore how DPR uses Virtual Design and Construction and Self-Perform Work to deliver successful projects.

Roy Malcolm

Roy leads the development, implementation and support of VDC workflows across DPR’s Central Region. A 2012 Building Construction graduate from Virginia Tech, he brings strong experience in implementing and executing VDC strategies that add value to DPR projects. As Central Region VDC Leader, Roy supports project teams across Texas in leveraging established VDC technologies both in the office and the field. He also provides guidance on model-based project management, process workflows and construction technology deployment from preconstruction through closeout.

Outside of construction, Roy enjoys sampling local craft beer and wine, hiking with his wife and working on his family’s cattle farm in the mountains of Virginia.

Matt Lagusis

Matt Lagusis is the Concrete VDC Manager at DPR Construction, based in Austin, Texas. With nearly 30 years of hands-on experience in concrete reinforcing, Matt began his career as a field ironworker and has since held roles including rebar detailer, fabrication production manager, 3D modeler and project manager/technical designer at a structural engineering firm.

His broad expertise spans fabrication, detailing and design-assist collaboration, making him a key contributor to complex, high-performance projects. Matt is widely recognized for his ability to navigate technical challenges and his steadfast commitment to innovation — qualities that consistently lead to successful outcomes in collaborative delivery environments.

Outside of work, he enjoys exploring with his wife and adult sons, practicing Brazilian jiu-jitsu (he holds a purple belt) and restoring vintage automobiles.