The rise of advanced digital tools has reshaped how mechanical contractors design and execute complex projects. Two practices sit at the center of this shift: Virtual Construction and Virtual Fabrication. Together, they anchor modern Virtual Design & Construction (VDC), changing how teams develop ideas, validate decisions and move work into production.

At Harris Design Studio (the engineering, VDC and technical services arm of Harris), these methods create a more predictable and fabrication-ready process from the earliest stages of design. Designers, building scientists and constructability specialists work in a shared digital environment that strengthens coordination and gives teams clearer insight before work reaches the field.

A solid grasp of Virtual Construction and Virtual Fabrication reveals how these digital practices support efficient, reliable outcomes in design-build delivery.

Best practice VDC goes beyond 3D modeling. It is used not only for design development, system coordination and fabrication preparation but also other planning techniques such as immersive Virtual Reality (VR) reviews and automation for production of deliverables. Increasingly by integrating more and more of these tools, our Design Studio delivers greater accuracy, consistency and value across every stage of a project.

Understanding Virtual Construction

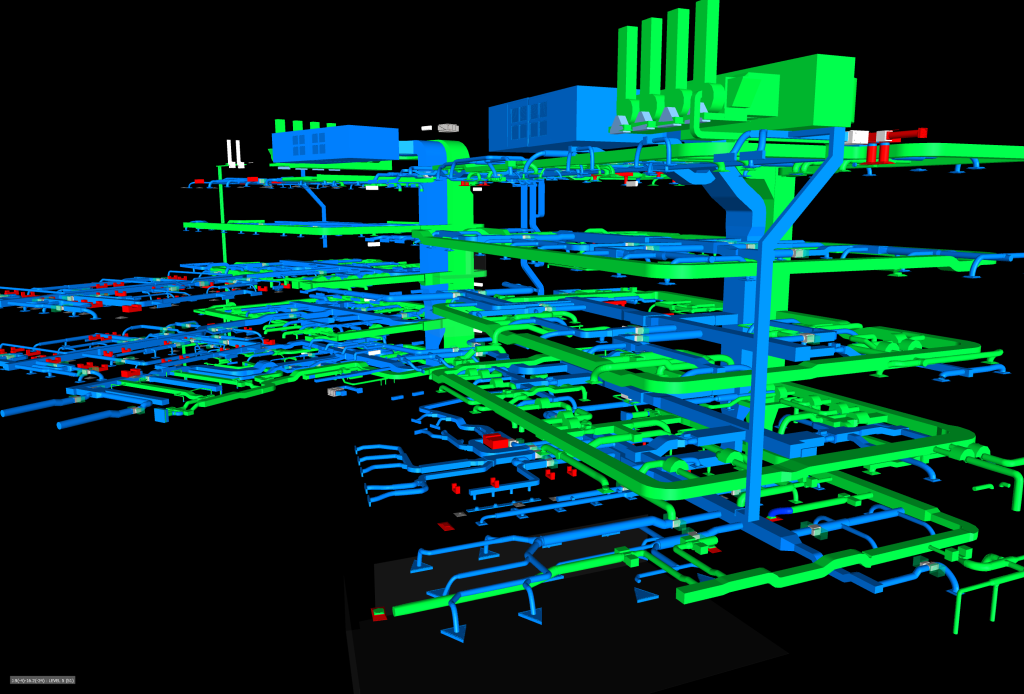

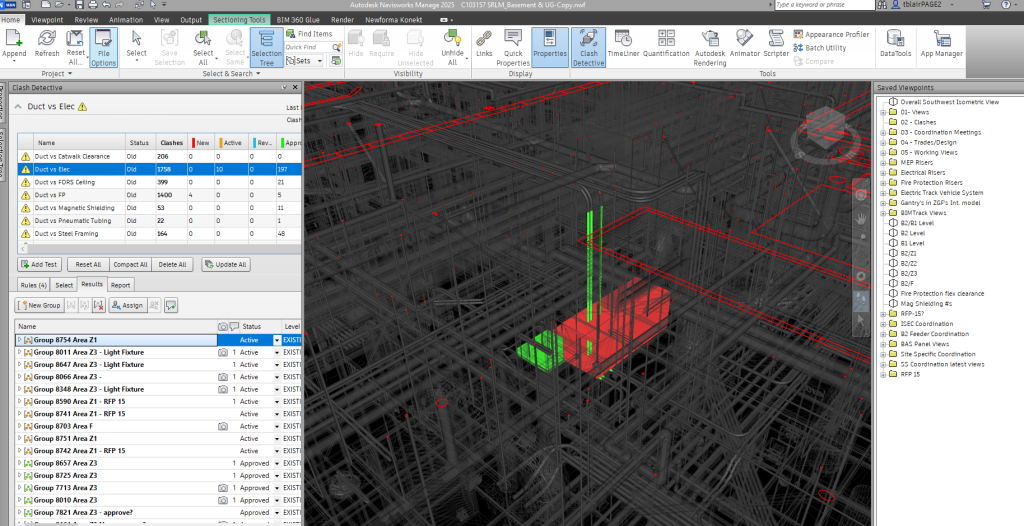

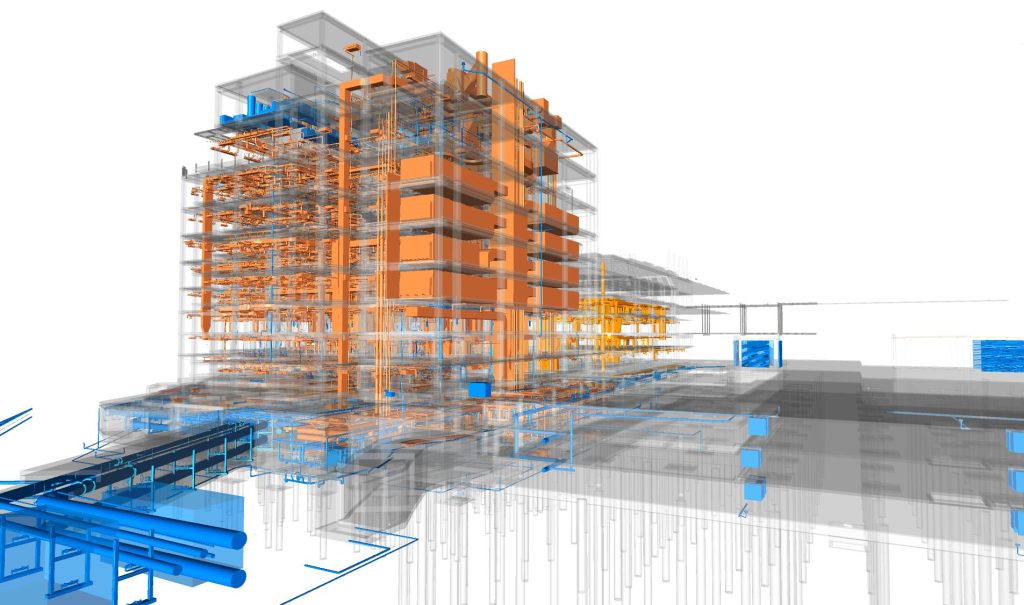

Virtual Construction refers to the use of digital models and simulation tools to understand a project long before work begins in the field. With detailed Building Information Models (BIM), teams can test design ideas, reveal conflicts and map out installation sequences in a controlled digital environment. This early visibility strengthens decision-making and reduces uncertainty downstream.

- Building Information Modeling (BIM): The foundation of Virtual Design & Construction, BIM integrates architectural, structural and trade model components into a single, coordinated model.

- Clash Detection: Virtual models help identify and resolve design and trade conflicts early, reducing costly rework during construction.

- 4D and 5D Simulation: Adding time (4D) and cost (5D) dimensions to BIM enables teams to simulate construction schedules and budgets, produce schedules of values based on planned versus actual work and improve overall project predictability.

- Enhanced Collaboration: Cloud-based platforms allow both real-time and scheduled time collaboration among architects, engineers, contractors and Owners to keep everyone aligned.

Virtual Fabrication

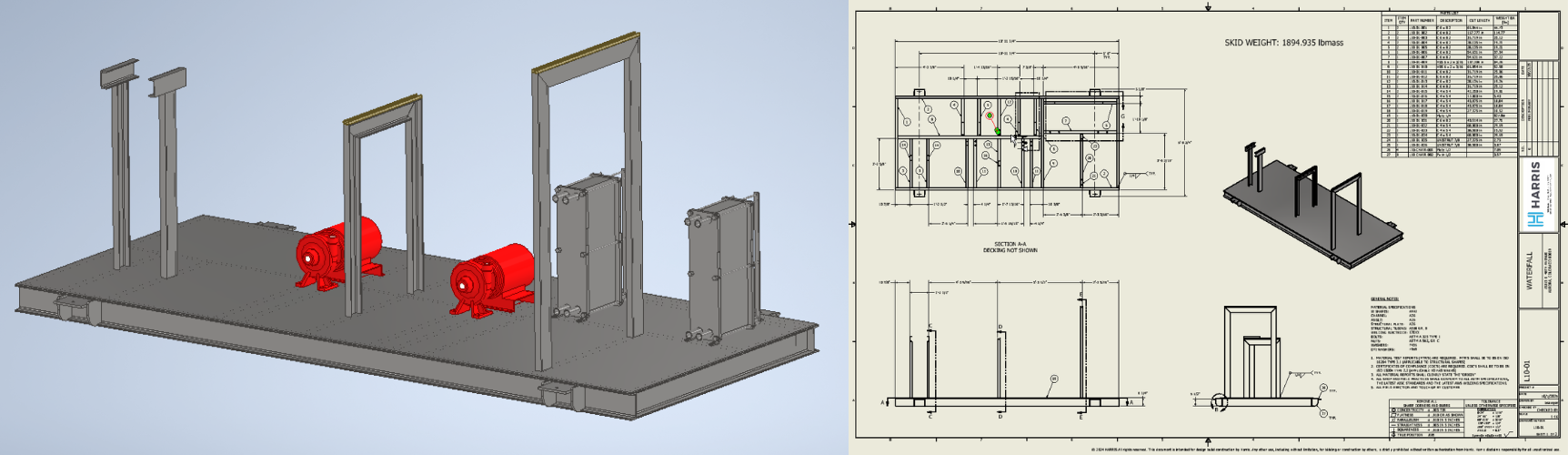

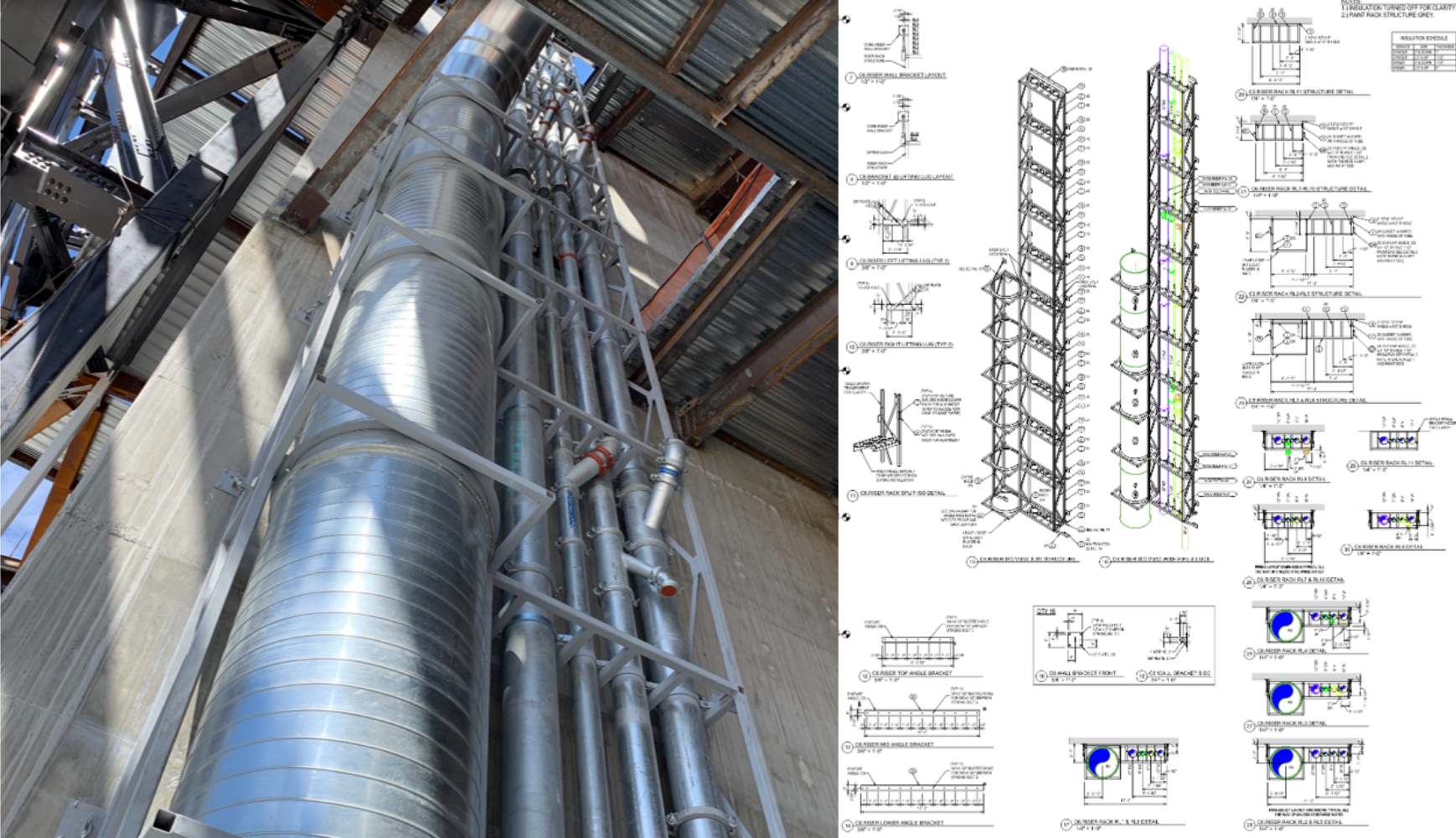

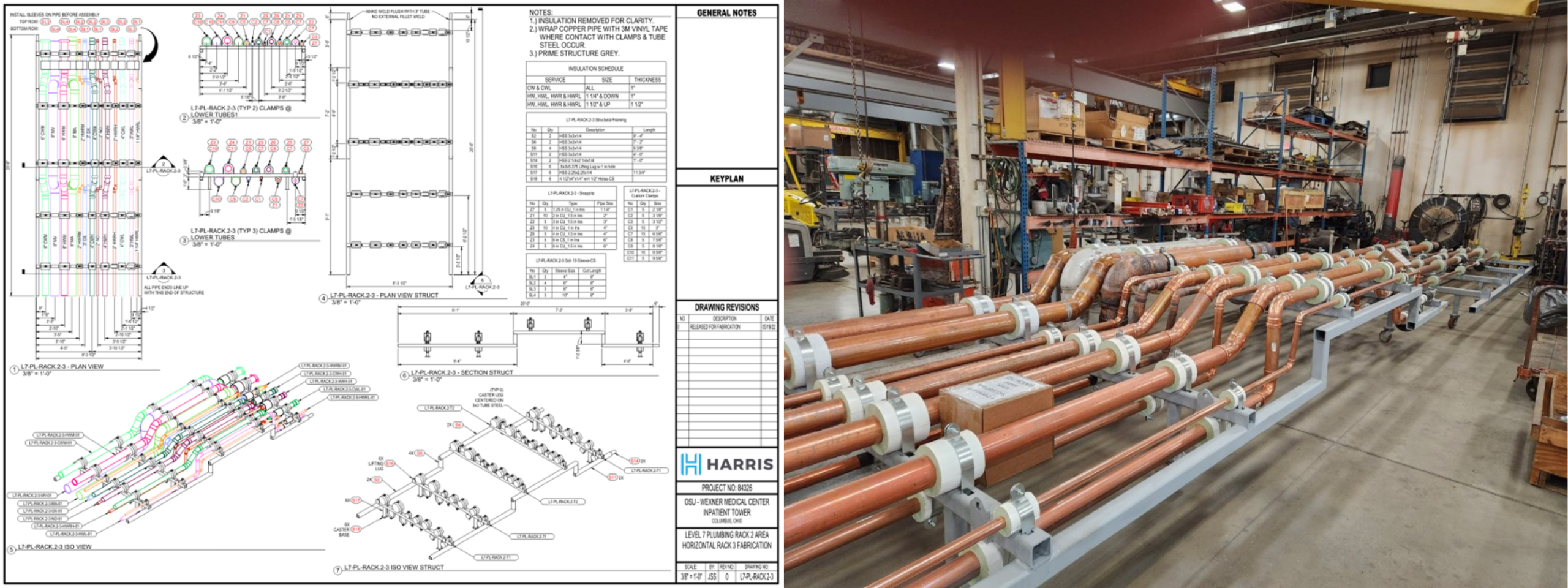

Virtual Fabrication carries the digital process into production, turning coordinated models into build-ready information. Instead of stopping at system layout, teams refine components in detail and test how assemblies will come together before any material is cut. That level of preparation reduces uncertainty during installation and helps crews move more efficiently whether the work is done off site or assembled in the field.

- Digital Prototyping: Components are modeled in detail, allowing for precise fabrication and minimizing errors during manufacturing.

- Prefabrication and Modular Construction: Virtual Fabrication facilitates the production of building elements in controlled environments, improving quality and reducing construction time.

- Integration with Supply Chain: Fabrication models can be linked directly to suppliers and manufacturers to streamline procurement and logistics.

- Quality Assurance: Virtual checks ensure fabricated components meet design specifications before they arrive on site.

- Stratus Integration: Harris utilizes Stratus, a cloud-based Manufacturing Resource Planning (MRP) software that connects BIM models directly to the shop floor. This bridges the gap between design and fabrication and creates a seamless digital workflow. By connecting Revit-based models directly to fabrication processes, Stratus enables real-time tracking of parts, materials and assemblies. This integration enhances communication between VDC teams, fabrication shops and the field.

Together, Virtual Construction and Virtual Fabrication create a connected digital workflow that supports smarter decisions well before work reaches the field. Virtual Construction sharpens the design side by revealing how systems interact and where conflicts may arise. Virtual Fabrication carries that precision into production, shaping how components are built and assembled. When these processes come together early, as they do in design-build environments, the result is a smoother path from concept to installation with fewer surprises and far steadier project delivery.

Benefits in Design-Build Projects

Design-build projects within Harris Design Studio are especially well-suited to benefit from VDC methods and processes. These methodologies foster collaboration, accelerate project delivery and enhance overall quality. Because design-build brings designers, builders and key decision-makers together from day one, VDC has the unified information flow and early alignment it needs to deliver its full value.

- Streamlined Communication: Unified digital models reduce misunderstandings between design and construction teams, ensuring everyone works from the same information.

- Accelerated: Early detection of issues and prefabrication of components compress project timelines and minimize delays.

- Cost Savings: Accurate modeling and fabrication reduce waste and rework, leading to more predictable budgets.

- Risk Mitigation: Virtual simulations allow teams to foresee and address potential risks before they impact the project.

VDC Technology Utilization

Harris leverages VDC technologies alongside our design-build approach to reduce rework throughout both the design and construction phases. Integrating virtual designers with our constructability specialists allows us to define the best build approach early and align the design with fabrication-ready components. This approach also enables us to specify anticipated materials and equipment up front, rather than relying on generic model elements, resulting in fewer design changes and RFIs during trade coordination and construction.

In addition, our use of VDC technologies streamlines document control and communication across project teams. Integrated digital workflows reduce response times, minimize latency and ensure everyone is working from the most current and accurate information.

Innovation in Action with Next-Generation Tools

Our Automation Processes support efficiency by taking on repetitive production tasks through customized digital workflows and smart tools. Automating portions of the VDC process improves modeling consistency and reduces manual effort across coordination, data extraction, parametric family creation and documentation. This allows teams to concentrate on design intent and system performance rather than time-consuming production steps.

The value of these tools becomes clear on large, technically complex design-build projects. One recent Maryland project (more than half a million gross square feet and served by dedicated, resilient mechanical systems) required extensive modeling: over 100,000 linear feet of ductwork, 170,000 feet of primary chilled and heating water, 15,000 feet of steam and condensate, 90,000 linear feet of plumbing and 45,000 feet of medical and lab gas piping. Automation enabled the team to generate more than 1,300 drawings during the Construction Document phase, a workload that would not have been feasible on schedule through more manual methods.

Virtual Reality (VR) adds another layer to this approach. Immersive model reviews give clients and project teams the ability to examine mechanical systems in their installed context before construction begins, helping them evaluate spatial conditions and identify coordination issues early. This has been particularly effective on prefabricated modular assemblies, where early alignment and customer buy-in are essential before fabrication starts.

Conclusion

When Virtual Construction and Virtual Fabrication are fully embedded in design-build projects, the entire delivery process changes. Decisions come earlier. Coordination improves. Fabrication becomes more predictable. Harris Design Studio treats these digital practices as essential infrastructure that turns complex mechanical systems into buildable, reliable solutions. This approach produces stronger project outcomes and sets a higher bar for what clients can expect from modern mechanical design.

About the Authors

Harris Design Studio

Harris Design Studio is the engineering, VDC and technical services arm of Harris, a leading national mechanical contractor. They are a dedicated team of designers, building scientists and VDC specialists who bridge the gap between design and construction.

Nate Nielson

Nate Nielson serves as the Sr. Director of Virtual Construction and Virtual Fabrication at Harris Design Studio. He completed a sheet metal apprenticeship with Local 312 in Salt Lake City, UT, and holds a bachelor’s degree in integrated studies with concentrations in Construction Management Technology and Design Graphics Engineering Technology from Weber State University.

With over 30 years of industry experience, his career reflects a sustained commitment to expertise and professional advancement in the fields of construction and engineering.

Luis Chanona

Luis Chanona is an architect with extensive experience contributing to BIM and VDC implementation across multiple companies in Mexico. He has been involved in diverse project types, including cinemas, fuel storage terminals and rail terminals. He also spent four years working on the New International Airport of Mexico, where he distinguished himself as a BIM Manager by reviewing approximately 3,500 BIM models totaling over 538 million square feet.

With a strong background in architecture, structural coordination and MEP systems, Luis now leads the Virtual Design + Technology group at Harris Design Studio.

John Gregory Williams

John Gregory Williams is a creative problem solver and driven engineering leader and with more than 20 years of experience in the design and construction industry. He has a passion for the built environment and enjoys using his experience and skills in design leadership, sustainability, project management and MEP/Utilities systems engineering.

As the leader of the Harris Design Studio, John is responsible for the cultivation and care of business relationships and manages all Design-Build and Design Assist projects while also overseeing traditional delivery support. He has led the mechanical design for many landmark buildings, including the innovative Apple Park in Cupertino, CA, and the new SRLM facility at the NIH.