Editor’s Note: This is Part 1 in DBIA’s “Design-Build in Times of Crisis” series, exploring how collaborative delivery has transformed America’s response to emergencies, from terror attacks and natural disasters to today’s growing climate and infrastructure threats. Stay tuned for Part 2, “Delivering Under Pressure: Design-Build’s Role in Today’s Crisis Response,” coming soon. Sign up to hear about new stories from DBIA first.

In the aftermath of a disaster, infrastructure is more than a public service. It’s a lifeline. Roads aren’t just roads; they’re access to medical care. Bridges aren’t just crossings; they’re the difference between isolation and connection. And when the pressure’s on, Owners don’t have time for business-as-usual delivery.

They need speed. They need resilience. They need a collaborative team ready to mobilize at a moment’s notice and deliver resilient solutions just as fast as the crisis demands them.

That’s exactly the kind of moment where design-build has proven its value time and again. Especially in emergency response and disaster recovery, collaborative delivery is the smarter choice. It aligns the right people early, eliminates barriers and adapts in real time, often while the waters are still rising or the road is still crumbling.

We’ve seen this firsthand across the country, from bridges rebuilt before the next storm hits to causeways restored well ahead of schedule. Beyond asphalt and concrete, design-build has reconnected entire communities through trust, transparency and teamwork.

As climate and weather disasters, infrastructure failures and public safety emergencies become more common, design-build continues to demonstrate its effectiveness as the delivery method best equipped to meet these moments, delivering projects up to 102% faster than traditional design/bid/build.

Why Collaborative Delivery Rises to the Moment

Design-build works in a crisis because it’s built for clarity under pressure. Traditional delivery methods separate design and construction, often delaying mobilization, fragmenting communication and slowing decisions. In contrast, collaborative delivery brings everyone to the table from the start. That unity certainly brings efficiency, but in emergency response, it does more than streamline processes. The collaboration baked into Design-Build Done Right® becomes a lifeline, allowing teams to respond faster, adjust in real time and stay aligned under pressure when rebuilding a sense of “normal” is the goal.

Key advantages include:

- Speed to Mobilize: Teams begin work before final designs are locked, with phase overlap accelerating delivery.

- Real-Time Adaptability: When scope evolves or conditions shift, the team shifts with it, leading to fewer change orders.

- Shared Accountability: Budget and schedule risks are actively managed by a unified team with aligned incentives. For Owners navigating high-pressure environments, this structure minimizes risk and maximizes control, empowering faster decisions without sacrificing oversight.

- Innovation Under Pressure: Cross-discipline collaboration sparks solutions faster, especially in unfamiliar terrain.

In a crisis, there’s no time to draw lines between “designer” and “builder.” Design-build blurs those lines in the best possible way, and that makes all the difference.

A Legacy of Rapid Response

While the national spotlight on design-build has grown in recent years, its roots in emergency response run deep. For decades, collaborative delivery has helped communities recover faster, safer and stronger after a crisis.

Take the Pentagon’s Phoenix Project in 2001. After the 9/11 attacks, the design-build team reconstructed the damaged section in less than a year, 28 days ahead of schedule and $194 million under budget. The project was part of the broader Pentagon Renovation Program, a 10-year, $4 billion effort led in part by Walker Lee Evey, who served as DBIA’s President from 2004 to 2009. That program — and the Phoenix Project within it — demonstrated how collaborative delivery could succeed even under extraordinary circumstances. The lessons learned helped shape DBIA’s Owners Series of education and exemplified what would later be formalized as Design-Build Done Right® best practices. The Phoenix Project remains one of the most iconic examples of design-build’s power to deliver clarity, unity and speed when they’re needed most.

Another early example came in 2002, when the West Flagler Street Bridge in Miami suffered a structural collapse. Under a Declaration of Emergency, the Florida Department of Transportation (FDOT) partnered with design-builder PCL Construction to restore the bridge and reopen the major downtown thoroughfare. Within just seven days, the team installed a temporary control house using prefabricated components, and a permanent structure followed in just six months. This project earned DBIA’s 2003 National Design-Build Award – Civil Category (Under $15 Million) and highlights how design-build has long empowered Owners to act quickly, think creatively and restore critical infrastructure under pressure.

In 2005, Hurricane Katrina devastated Louisiana and Mississippi, leaving critical infrastructure in tatters. Design-build played a key role in rebuilding bridges, pump stations and emergency headquarters. These projects consistently outpaced traditional timelines, offering recovery in months rather than years.

For instance, three flood-damaged pump stations in St. Bernard Parish were rebuilt in just 18 months, an entire year faster than conventional methods typically allow. Led by the U.S. Army Corps of Engineers (USACE), with work performed by CDM Smith, the $20 million effort focused on restoring operations and improving resilience by elevating equipment and integrating stormproofing measures. The project replaced damaged pumps, electrical systems and generators, ensuring the stations could remain operational during future storm events. These improvements restored critical flood protection before the next hurricane season and laid the groundwork for continued infrastructure upgrades in the region.

Meanwhile, the $283 million replacement of the U.S. 90 Bay St. Louis Bridge (Mississippi) cut a typical four-to-five-year delivery timeline in half, reopening a vital link for commerce and coastal communities in just two years. The design-build team was able to accelerate procurement and construction by overlapping phases and using innovative scheduling, all while maintaining quality and safety standards. This swift recovery restored not only physical connectivity but also economic stability for many Gulf Coast towns still reeling from Katrina’s impacts.

Design-build also helped Chevron rapidly relocate its Gulf of Mexico regional headquarters to Covington, Louisiana, after the storm. Led by Clayco, the design-build team overcame severe labor shortages, disrupted supply chains and 60 days of weather delays to deliver an 180,000-square-foot tilt-up concrete facility on time. Phase One finished a full month early, thanks to fast-tracked scheduling and close coordination between designers, engineers and contractors. The resulting headquarters is now recognized not only as a model of adaptive site planning and business continuity but also as a benchmark in hurricane-resilient design. Its performance during subsequent storms has further validated the value of collaborative delivery in mission-critical infrastructure.

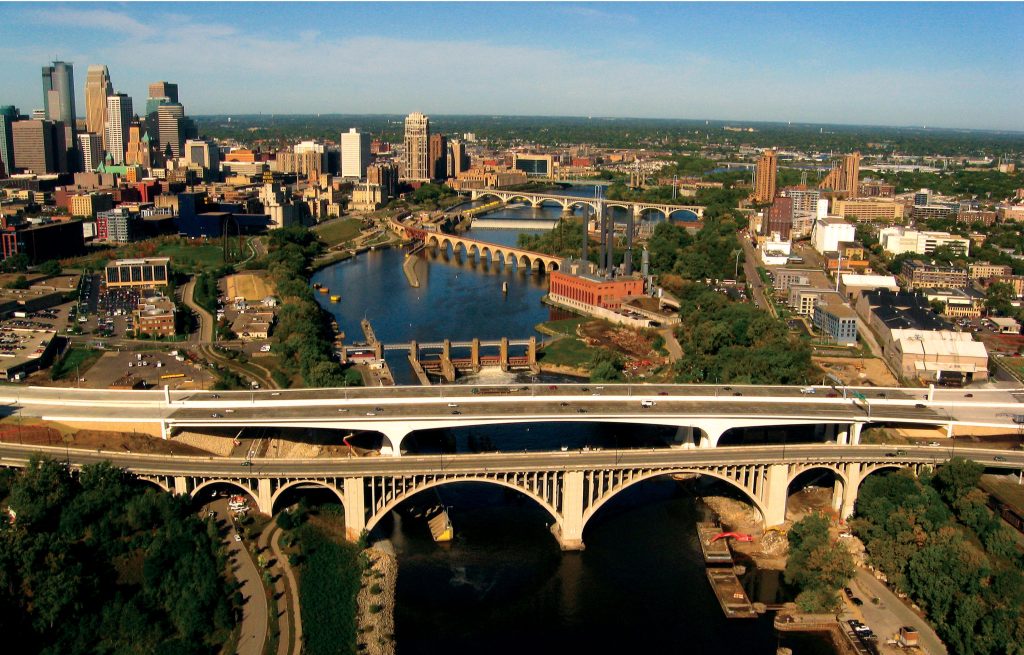

Following the catastrophic collapse of the I-35W St. Anthony Falls Bridge in 2007, the Minnesota Department of Transportation (MnDOT) turned to design-build to deliver a replacement under intense national scrutiny and an urgent timeline. The design-build team, including FlatironDragados (then Flatiron Constructors), worked around the clock, overlapping design and construction phases, maintaining 24/7 work shifts and leveraging accelerated decision-making processes. The result was a new bridge completed in just 11 months. Despite the compressed schedule, the project prioritized innovation and long-term durability, integrating post-tensioned concrete box girders and redundant structural elements to ensure safety and longevity. The bridge opened ahead of schedule and received widespread acclaim, including DBIA’s 2009 Best Overall Design-Build Project Award. More than a triumph of speed, the project became a national benchmark for emergency bridge replacement done right.

These projects were more than just rebuilds. They were inflection points, moments when design-build didn’t just restore what was lost but reimagined how we respond. In each case, collaborative delivery helped communities recover faster and smarter, building resilience into the process itself. Together, these projects reshaped the playbook for emergency response, proving that when time is scarce and stakes are high, a united team can rebuild with purpose, creating infrastructure that’s stronger, smarter and more resilient.

As climate and weather threats increase in frequency and infrastructure demands evolve, so too does the role of design-build. The next generation of crisis response will go beyond speed and budget to center resilience, sustainability and community. It’s about building back better, with an eye to the triple bottom line.

In Part 2 of Design-Build in Times of Crisis, we’ll explore how today’s design-build teams are meeting new challenges, from a global pandemic to back-to-back hurricanes, with the same clarity, coordination and resilience that built this legacy. Learn more about how design-build helps communities get back to business after tragedy strikes.